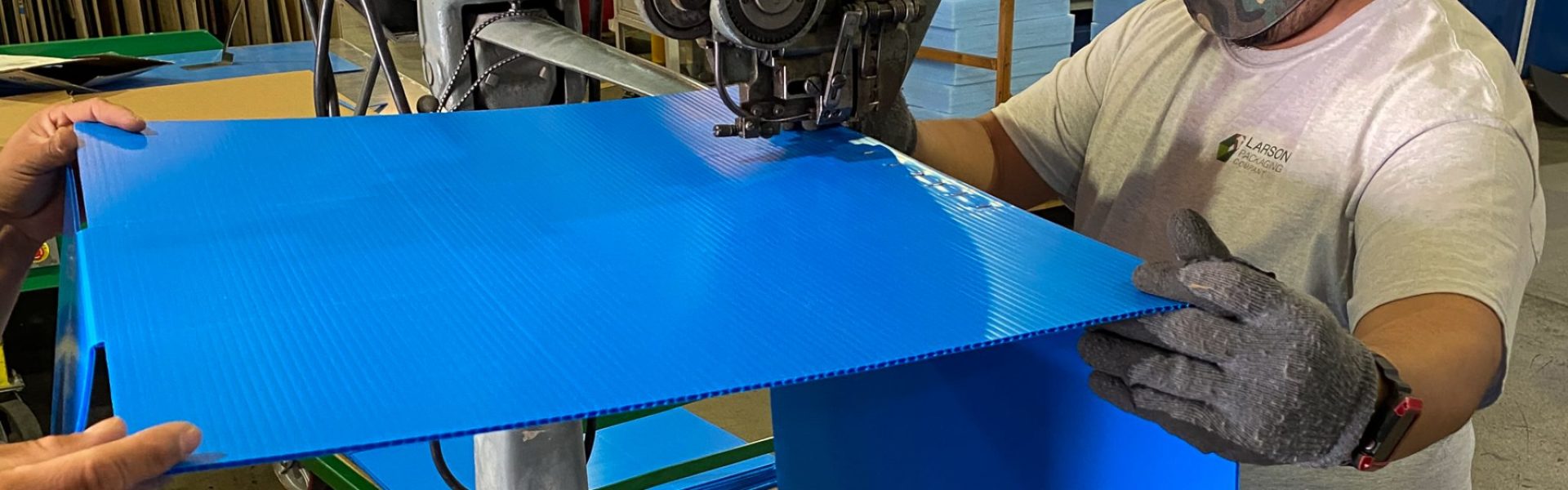

This new high-speed WARDJet waterjet cutter enhances our ability to manufacture fast and meet shipping guarantees while maintaining exceptional quality

We recently installed new, state-of-the-art equipment from manufacturer WARDjet in our facility. The WARDJet J-106 waterjet cutter is...

26 September 2023