New 2U Server Packaging Assembly design delivers a 10% saving

18 August 2023

Our customer was a packaging distributor working with a network appliance company. The goal was to design and manufacturer a new 2U server pack to reduce costs. The new 2u Server Packaging Assembly needed to stack 4-5 high, pass ISTA6B testing, and allow for the unit to be removed with a Genie lift.

Solution

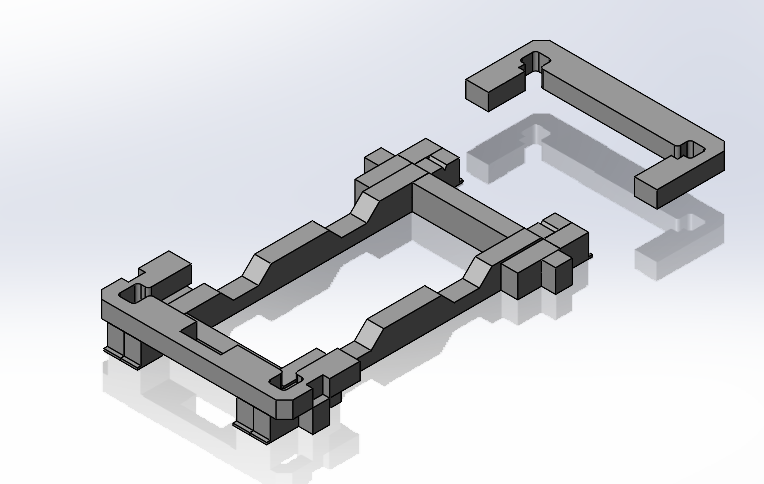

We replaced the 220 Ethafoam with a similar 220 HRC (High Recycled Content). We redesigned the bottom foam cap to utilize less material. And instead of heat-sealing the bottom foam, we designed an interlock mechanism to keep the joints in place and to save on labor time. For savings were generated by removing the V-board from the pallet/DST set without affecting performance.

Outcome

The new design delivered by the Larson Packaging Company Design Engineering team was a success. It met all the customer’s requirements and delivered a 10 % savings on the pack.