ABOUT US

Introducing Larson Packaging Company

We’re big enough to solve any packaging challenge, yet small enough to care about you, our customers

Larson Packaging Company and its employees are committed to consistently providing defect-free, custom industrial packaging products and services, on-demand, and with total customer satisfaction and continual improvement.

Established company

Operating since 1900 (as Larson Ladder company)

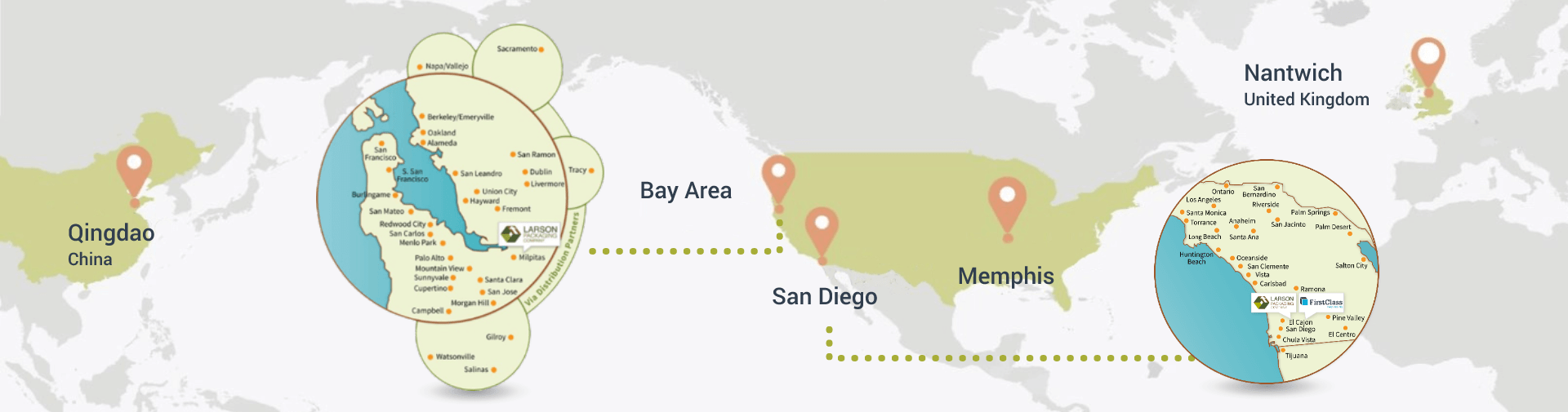

Local focus

100 years in Silicon Valley & over 30 years in San Diego

Global reach

Olive Branch, MS and partners in UK and China

Multiple plants

Milpitas, El Cajon and Memphis facilities

Comprehensive service

Solutions for all protective packaging needs

Multi-industry experience

Services for, and experience in, many industries

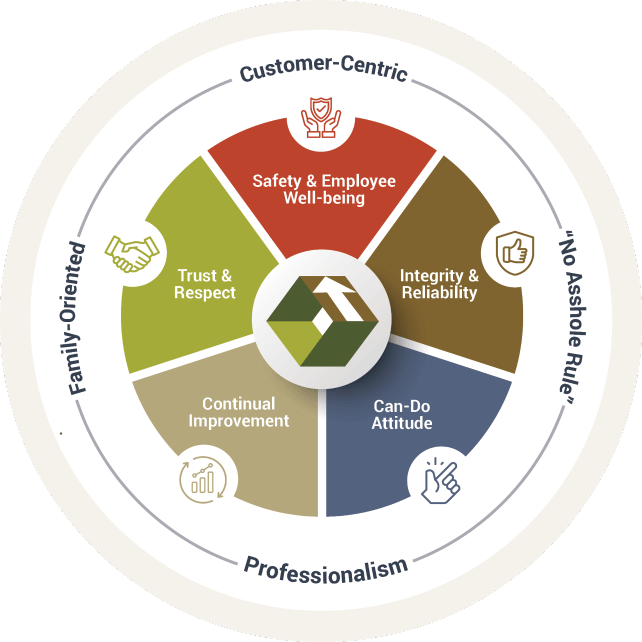

Our values are why we can develop and maintain real relationships with our employees, suppliers and customers

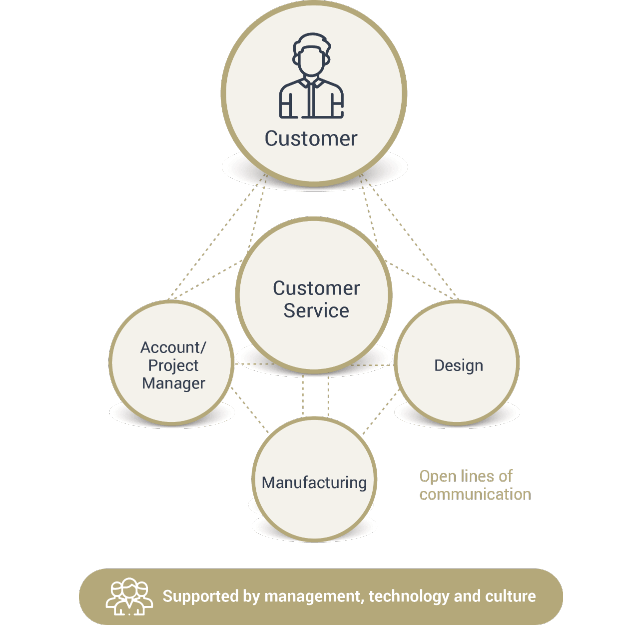

We empower our Customer Success Team with a flat, integrated management structure for fast, accurate decisions

Traditional siloed structures keep the customer at arm’s length. As a result, decision making is less responsive, and mistakes often creep into processes.

Four benefits of our radical management approach

Customization

We work with you to make a solution not sell you a product

Nimbleness

Line-level decision-making for speedy action

Accuracy

Right information on-hand for the right decisions

Frictionless

Enjoy a seamless vendor experience