OUR PRODUCTS

On-demand custom anti-shock and anti-vibration protective packaging solutions

Precision Packaging for Safe Transit

We have the capacity to manufacture a vast array of custom industrial protective packaging and shipping solutions all under the one roof. In particular, we are anti-shock and anti-vibration specialists and have the know-how and engineering capabilities to develop smart solutions to protect fragile, high-value equipment and products in-transit.

We’re also a foam fabricator, so you can rest assured that you’re always getting the best choice for your application. Plus, we take an engineering approach to design and foam specification versus just “rules of thumb” or what “looks good.” This means we engineer packaging guaranteed to endure the toughest transits—using precise substrates that are fabricated to exacting standards—so your products reach their destination in perfect condition.

Our industrial protective packaging solutions have seen more than $40 billion of sensitive medical, electronic, technical and military equipment shipped with zero damage.

All under one roof

Full line of packaging designed and manufactured all under the one roof—all with custom foams including Polyethylene, Polyurethane, Polypropylene, Anti-static and Cross-linked foam.

In-house engineers

Professional experienced packaging engineers working in Solidworks and as partners with customers’ engineering teams and program managers

Authorized dealer

Technical Packaging Dealer for Pelican-Hardigg and SKB case solutions.

Large inventory

Large inventory of raw materials, stock, and manufacturing inhouse = short lead times.

Customizations

Case and crate customization options: routings, wheels and casters, handles, hardware, colors, heat-treated and reusable.

Our protective packaging specialities

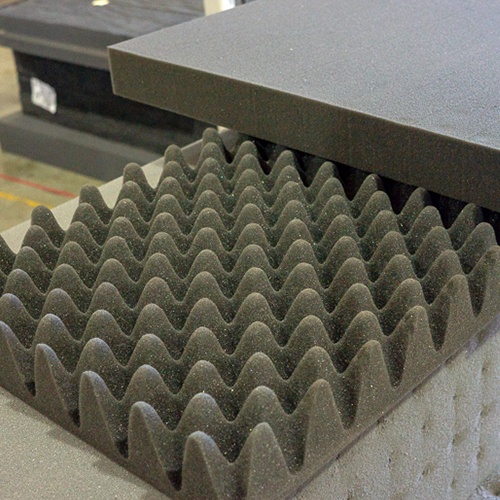

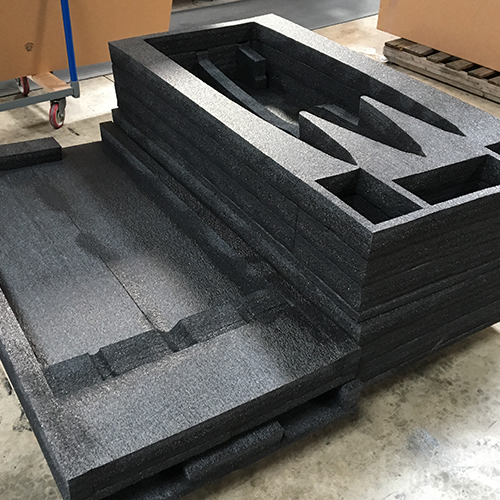

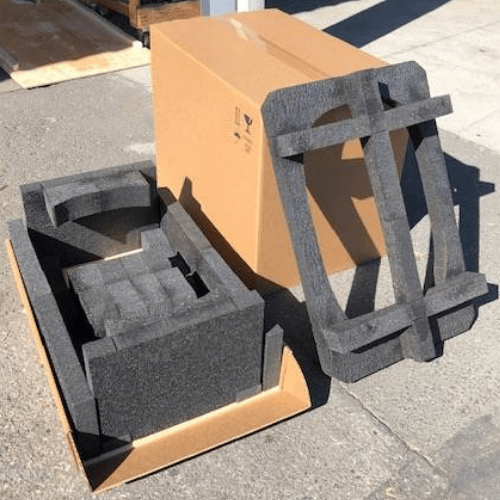

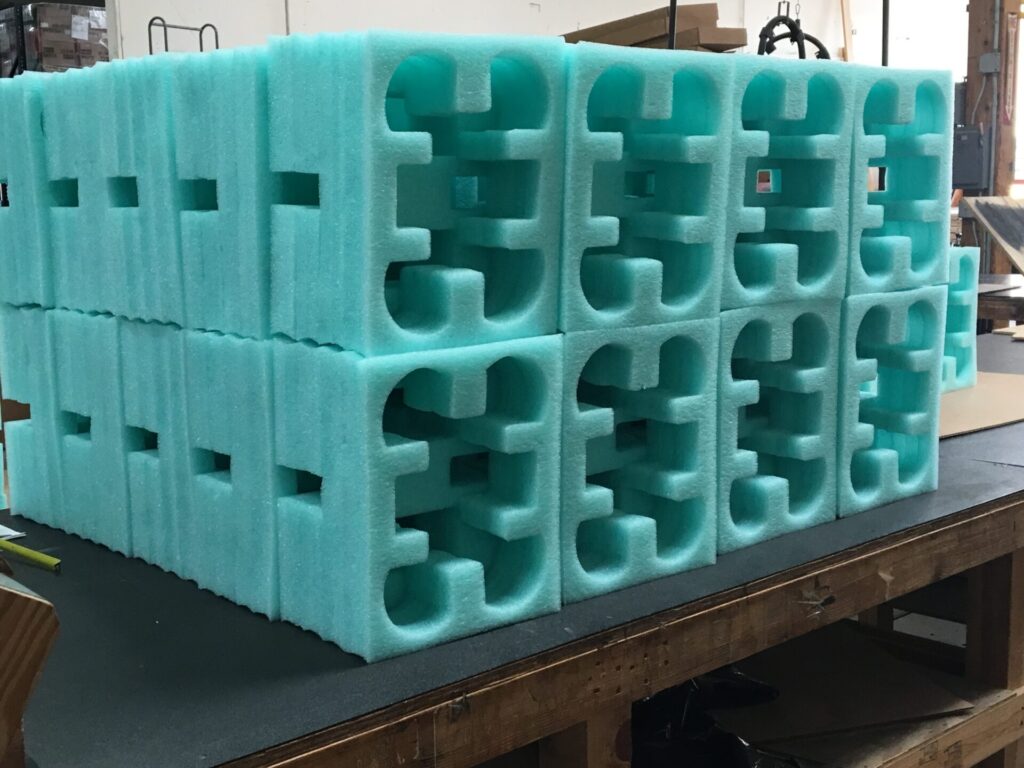

Foam sets and inserts

Polyethylene, polypropylene, polyurethane, and other protective foams all behave differently. We can identify the foam that will perform best for your application, and design, die-cut and assemble it for maximum in-transit protection with minimum expense.

- Foam caps and assemblies

- Plans and die-cut pads

- Case inserts and cushioning systems

Crates

We use Mil-Spec and ASTM standards as the starting point for wooden shipping crate design and custom-design for highly specialized material handling, loading and unloading, blocking and bracing, and shock and vibration protection requirements.

- Shock mount and vibration protective floater bases

- Wood and corrugated combo hybrids

- Heavy-duty skids

- Tool-less and re-use

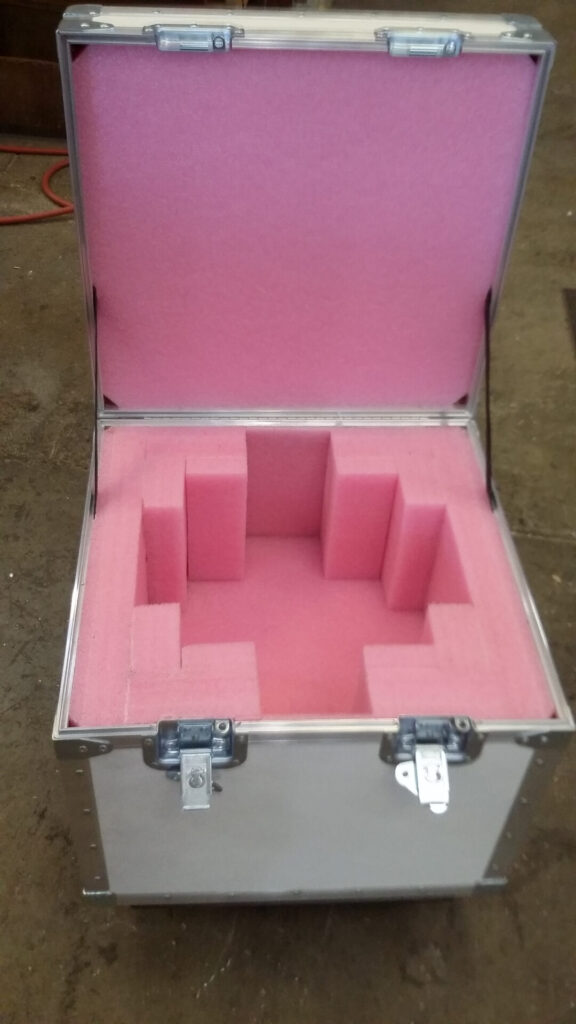

Cases (ATA, Pelican, and SKB)

Pelican and SKB hard cases to protect and move high value, sensitive, and delicate equipment and instruments that will be routinely and repetitively transported and stored.

- Storm Cases, Pelican-Hardigg Cases, Pelican Air Cases

- Mil-Standard SKB Cases

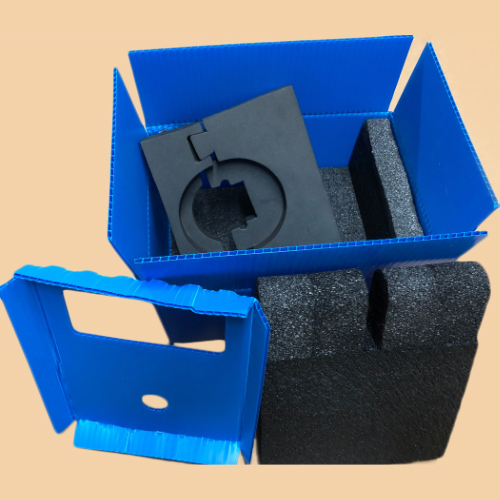

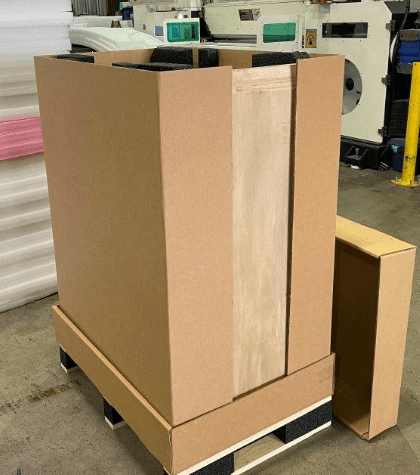

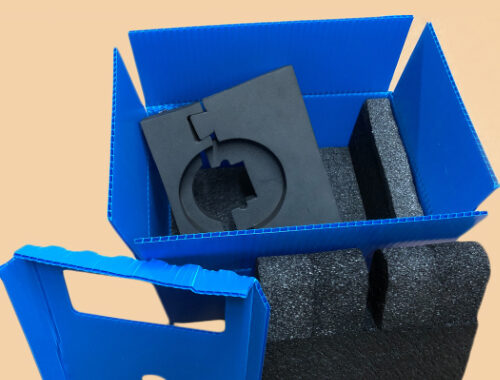

Hybrid packaging

An intelligently designed hybrid corrugated pack can offer the same shipping protection as wood but at a reduced weight and manufacturing cost. It is also much better for the environment as much of the packaging can be recycled and the cardboard, foam etc fits in normal waste streams.

REQUEST QUOTE MORE INFOOn-demand box and foam

Many packaging manufacturers just aren’t interested in short, custom-packaging runs of corrugated boxes. Our on-demand service does runs under 500 units and is especially cost effective. We can do large runs too.

REQUEST QUOTE MORE INFOPallets and other wood packaging

We customize both Stringer and Block pallets for your specific unit load size, handling environment, and shipping requirements. Any size, any quantity. We also offer standard sizes common to many consumer products.

REQUEST QUOTE MORE INFO